Our value proposition

Our food group offers high-quality, nutritionally sound products for people, plants, and animals, ensuring food safety through complete traceability at all stages of production.

Furthermore, as a food group committed to the environment, we dedicate significant effort and resources to transforming the byproducts of our operations and reintroducing them into the value chain, promoting a circular economy model through sustainable innovation that optimizes the use of natural resources.

Our value chain

A proprietary process that guarantees quality, traceability and sustainability.

Feed processing

The first stage in our value chain is the production of high-quality feedstuffs, which we use to feed our pig herds. They are essential to nourish the animals and ensure they grow healthy and strong.

We internally manage the formulas and characteristics of the feed, adapting them both to the needs of the animals and to the specific requirements of our customers. This autonomy allows us to offer a customized feed and guarantee optimum nutritional quality in each case. Thanks to this, we do not depend on third parties and we can meet the most demanding expectations.

Farms

Thanks to the vertical integration of weRfoods, we directly manage the breeding, care and traceability of our sows. This allows us to optimize genetic quality and guarantee a high level of pig production.

We have farms distributed throughout the national territory, which reinforces our autonomy and response capacity. We continue to grow with new farms and greater production capacity, which allows us to better adapt to the needs of our customers.

In addition, our commitment to animal welfare is endorsed by certifications such as the animal welfare seal. We are also committed to innovation, with electronic systems that monitor the individual feeding of each pig, and to the circular economy, reusing by-products and using solar energy for a more sustainable production.

Meat processing

We have a meat processing center that allows us to precisely manage this key stage of the value chain. All our processes are efficient and comply with the strictest food safety and animal welfare regulations, thanks to advanced traceability systems that guarantee control of each phase.

Our specialization in the pork sector, with more than 75 years of experience, gives us a competitive advantage. This knowledge, together with technology, allows us to reduce costs, improve quality control and export to international markets with different sanitary requirements.

In addition, this phase drives us to innovate continuously, not only in processes and products, but also in sustainability. We apply the circular economy to take advantage of by-products and reduce waste, and we were pioneers in obtaining the AENOR Zero Waste certificate, thus reinforcing our commitment to responsible management.

Thanks to this approach, the processing center has been a key driver of our growth: in the last decade we have increased our production by 83% and today we are one of the top 50 industrial companies in exports in Catalonia. We have also consolidated our position as one of the main exporters in Girona, with a firm commitment to quality and continuous improvement.

Natural casing products

We take advantage of the full potential of the products generated during our meat activity to promote a more circular and efficient economy. At this stage, we produce and market natural casings and offal from beef, pork and lamb, used in the production of sausages.

These products, highly valued in international markets such as Asia, reflect our commitment to sustainability by transforming by-products into useful and marketable new resources.

We also implement continuous improvements in our processes and facilities, such as the use of solar energy, to move towards more responsible and efficient production.

Production of cured and cooked products

We have a division specialized in the traditional production of cured and cooked pork sausages of the highest quality, adapted to the demands of the national and international market.

Thanks to our vertical integration, we guarantee the agile supply of raw materials and an efficient production that adapts to the needs of each customer: from specialized stores to large supermarkets and distributors.

Over time, we have perfected our recipes and processes, adjusting flavors, ingredients, formats and nutritional values. Our certifications -such as IFS, SAE or the Serrano Ham Certificate- reinforce our commitment to quality and position us as a benchmark in the food sector.

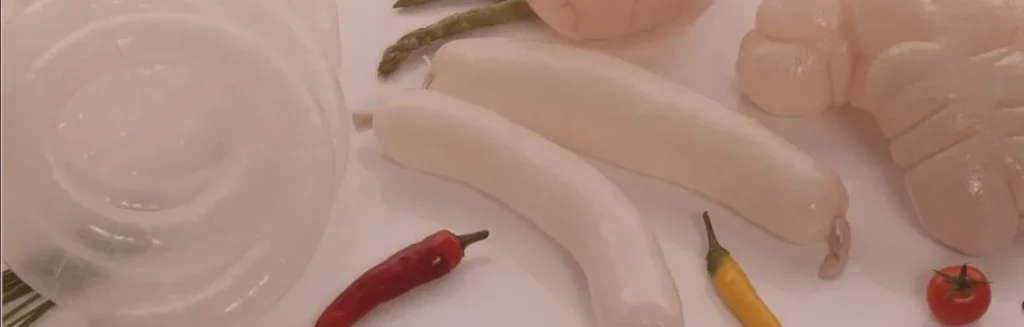

Processed meat products

Our specialized division transforms, deep-freezes, packages and markets a wide range of meat products, designed for sectors such as Industry, HORECA and Food Service.

Thanks to the raw material from meat processing and our vertical integration, we guarantee traceability, quality and food safety throughout the entire line. We are IFS certified, which supports the high standards of this business unit.

We offer practical, safe and quality products, designed to facilitate the daily work of chefs and operators in the sector. Agility, adaptability and continuous innovation are key to respond effectively to the needs of today’s market.

Animal nutrition

At weRfoods we produce high quality pet food, reflecting our commitment to the circular economy and animal welfare. This line of business opens new opportunities and adds value to every step of the production process.

Our focus on R&D has allowed us to innovate in the field of animal nutrition. We produce homemade burgers for dogs with 100% natural ingredients, cooked in a certified kitchen and delivered directly to homes.

The recipes have been formulated by nutritionist Milka Kosanovic Tesla, an expert in animal nutrition with more than 15 years of experience. Thanks to her knowledge, we guarantee healthy, balanced products adapted to the specific needs of each animal.

Fertilizer production

At weRfoods we also transform meat processing by-products into compost and organic fertilizers of animal origin. They are highly technical, agronomically proven and completely sustainable.

Our plant is designed to maximize the use of resources and ensure sustainability at every stage. We apply the 5 R’s philosophy (Recycle, Reuse, Reduce, Repair and Rethink) to minimize environmental impact and optimize the production cycle.

One of our main challenges is to develop ecological fertilizers of high agronomic value, reflecting our constant efforts in innovation. Thanks to our integration with the rest of the group, we reduce costs and add value through efficient marketing, positioning ourselves as a benchmark in sustainability within the agricultural sector.

Group companies

Novafeed

Novafeed, experts in the manufacture of feedstuffs

Novafeed is the division specialized in the manufacture of high quality compound feed. Its main competitive advantage is to guarantee a constant supply of top quality feed and to maintain total control and traceability in animal feeding, thus ensuring the highest production standards.

One of its great strengths is the ability to customize products according to the needs of each type of livestock (pigs, cattle, sheep, poultry), taking into account factors such as genetics, origin and sanitary conditions of each farm.

Quality is a priority. For this reason, Novafeed applies a rigorous control in the selection and reception of raw materials, subjecting them to chemical and microbiological analysis. In addition, it has a specialized technical service that evaluates and monitors each formulation.

With certifications such as ISO 9001:2015 and others in traceability, Novafeed reinforces its commitment to excellence. It also stands out for adopting sustainable practices in the development of formulations that minimize nitrogen emissions, reducing environmental impact.

Thanks to this comprehensive and customized approach, Novafeed has consolidated its position as an essential partner in the weRfoods value chain, guaranteeing quality, sustainability and efficiency in food production.

Agroporc

Agroporc, experts in the management of livestock farms

Specialized in pig breeding and growing, Agroporc manages a wide network of farms that guarantees a constant supply of high quality raw material for the group. This network provides stability even in the most complex moments. All its production is destined for weRfoods, with absolute control of traceability and the highest quality standards.

Agroporc’s daily work reflects the values of weRfoods. Its team takes care of the animals 365 days a year, including holidays such as Christmas or Easter, showing a high level of commitment.

What makes Agroporc special is its human approach. It provides opportunities to people who have been through difficult situations, such as people from other countries who face barriers and limitations. Trust and mutual commitment are essential to operating effectively and autonomously in an environment where direct supervision is not always available. This approach highlights the resilience and sacrifice of the team, pillars that enable the division’s success and contribute to weRfoods’ leadership in the sector.

Friselva

Friselva, specialists in the meat processing industry

Friselva is a key pillar in the weRfoods value chain. Since its beginnings, it has been synonymous with excellence and innovation, achieving milestones that consolidate its leadership in the international market. It was a pioneer in Spain when it obtained ISO 14001 certification in environmental management in 2000, a reflection of its commitment to sustainability. The BRC and IFS certifications, obtained in 2009, have been key to its international expansion.

Its ability to adapt to demanding export requirements has driven its growth. With key approvals since 2005 (Japan and Korea) and 2010 (China), Friselva complies with the strictest global regulations. It currently exports more than 75% of its production to markets such as China, Japan, Korea, Germany, New Zealand, Uruguay and Mexico.

weRfoods values are deeply embedded in Friselva’s culture. Every step is guided by self-improvement, continuous improvement, integrity and commitment to quality and food safety. Friselva cultivates relationships of trust and solutions adapted to the real needs of the market.

Passion for their work is reflected in the day-to-day work of their team. Constant improvement, continuous learning and active listening to customers, suppliers and collaborators drive its success as a division and as an essential part of the group.

Tripnet

Tripnet, specialists in natural casings

Tripnet is recognized for its quality and innovation. Its integrated working model, in collaboration with Friselva, allows total control of the production process, guaranteeing impeccable traceability. This ensures not only excellence of the final product, but also efficient processes that generate trust and reliability.

Thanks to its dynamism and responsiveness, Tripnet understands and adapts with agility to international markets, especially in Asia.

Rafael Baró

Rafael Baró, tradition and innovation in cured and cooked foods

Rafael Baró combines more than a century of tradition with a modern approach to producing high quality products. This fusion of craftsmanship and innovation has allowed the division to continually adapt, maintaining its commitment to excellence at every stage of the process.

Its agility is one of its distinguishing features, allowing it to respond quickly to the demands of the market and its customers. As a result, it has achieved milestones such as homologation in the competitive Mexican market. This dynamism is the result of the commitment of a team that acts effectively in the face of challenges.

Humility is also an essential part of their identity: they recognize their achievements, but always seek to learn and improve. The passion for a job well done is reflected in the careful selection of raw materials and the dedication with which they face each process, positioning themselves as a benchmark of quality both locally and internationally.

Natural Jamón

Natural Jamón, tradition and excellence in each piece.

Natural Jamón is our brand specializing in serrano ham, which combines tradition and excellence at every stage of the process. Each piece is cured for a minimum of 9 months, which guarantees its quality and flavor. Thanks to this meticulous work, the division has reached a production of 500,000 Serrano hams per year, with the goal of reaching 600,000 in the coming years.

All Natural Jamón hams come exclusively from Friselva, which allows us to ensure complete control, from slaughter to final selection. Each product is produced under strict quality standards, whether bone-in or boneless, and the entire boning and packaging process is carried out internally at our curing facilities. This absolute traceability reinforces our commitment to excellence and attention to every detail.

Gicarns

Gicarns, production and distribution of processed meat products

Gicarns stands out for its commitment to quality, diversity and professionalism. Its mission is to facilitate the daily work of kitchen professionals, offering products that ensure regularity, safety and high performance. With constant adaptation to the market and innovative solutions, Gicarns offers gluten-free products that are safe and easy to handle, optimizing resources and reducing waste.

True to the values of passion and self-improvement, Gicarns continues to evolve to meet the most demanding expectations of its customers, consolidating its position as a reliable supplier in the restaurant and catering sector.

Bestial

Bestial, innovation in pet food

Bestial represents a breakthrough in innovation within the pet food sector. Born as a new B2C business model, this division applies the principles of circular economy to transform the way we understand the nutrition of our pets.

Since its creation, Bestial has revolutionized its offer, adjusting formulas and products to respond to market demands, incorporating new protein sources such as chicken or salmon.

In addition, its team works continuously to improve packaging, making it more sustainable and ensuring optimal product preservation. This commitment to useful and responsible innovation is also reflected in the development of new food supplements, with the aim of continuing to add value and consolidate its growth in the market.

ABF

ABF, fertilizer production with environmental commitment

ABF works every day with the purpose of building a more sustainable world. Thanks to its constant focus on continuous improvement, it has achieved great advances such as the stabilization of its production process, which allows them to always offer a homogeneous and high quality fertilizer, regardless of external conditions.

In addition, it has obtained Sohister’s ecological certification, a recognition that supports its commitment to the environment.

Thus, not only does it add value to the weRfoods production chain, but it also represents a clear example of how, with commitment and effort, solutions can be created that are beneficial for both nature and people.

ABF’s organic fertilizers have been the first to be commercialized within the circular bioeconomy program, consolidating itself as a pioneering proposal in sustainability.

Our presence

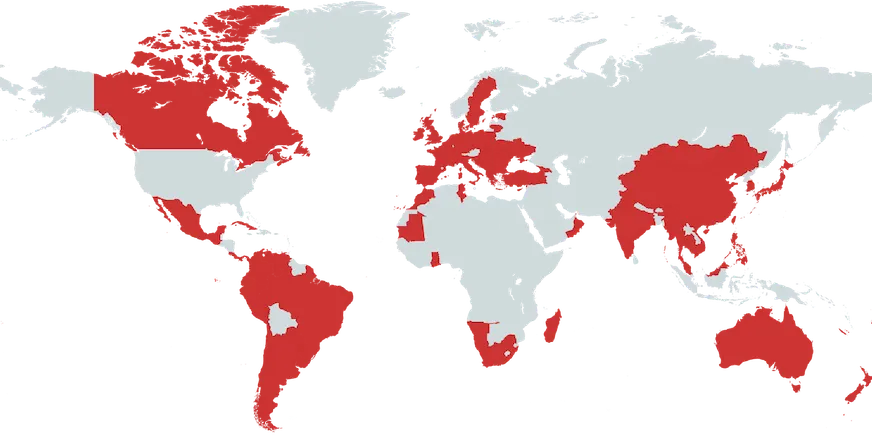

International

Committed to nourishing lives beyond our borders, we export to more than 50 countries, adapting to the demands of each market. This global expansion is a reflection of our passion to innovate and share our food expertise around the world.

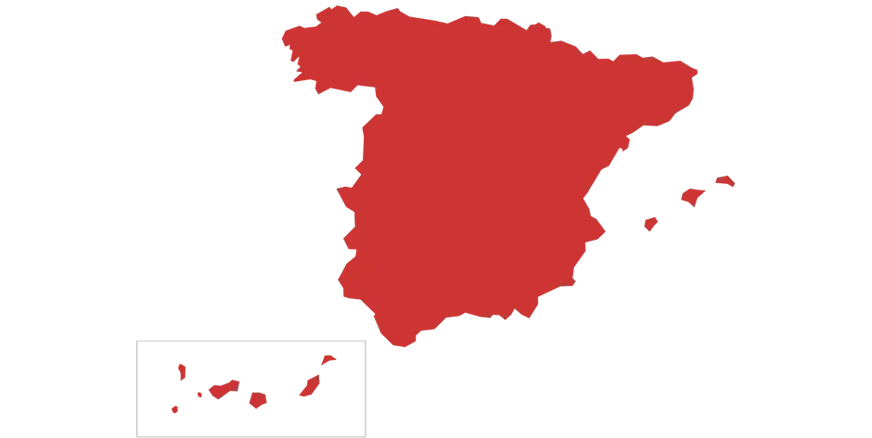

National

With a network of more than 280 farms and production plants distributed in key locations throughout Spain, weRfoods guarantees total control of every stage of the chain, from breeding to production and distribution.